Since its official launch to the international scientific community, MOVE4D technology—developed by the Instituto de Biomecánica de Valencia (IBV)—has sparked interest among research centers and companies across the globe.

This markerless 4D scanning system has demonstrated its potential not only in scientific research but also in key industrial applications, particularly in the design and customization of products based on human-body ergonomics and fit.

One of the first international institutions to adopt this technology was the Technical University of Dresden (TU Dresden), specifically the Chair of Textile Technology at the Institute of Textile Machinery and High-Performance Material Technology (ITM).

Recognized for its leadership in the development of cutting-edge textile products and simulation of advanced materials, ITM integrated MOVE4D into its technological strategy in late 2020.

A leap forward in textile research

The adoption of MOVE4D at ITM marked a turning point in how the interaction between the human body and clothing is studied. One of the main motivations for acquiring this technology was its unique ability to accurately capture both movement and static body shapes. Thanks to its speed, MOVE4D minimizes distortions caused by breathing or natural body sway during scans, providing far more reliable and objective data.

Professor Yordan Kyosev, Head of the Chair of Assembly Technology for Textile Products, explains: “MOVE4D gives us the possibility to analyze how human body geometry changes during motion, while also delivering very fast and accurate static scans. This means we can work with cleaner, more representative information.”

A pioneering laboratory and new research lines

At ITM, MOVE4D has been integrated into the “3D and 4D Scanning Lab”, alongside other 3D scanners already in operation. Yet its dynamic scanning capabilities have opened entirely new avenues of research. Today, the lab’s team of researchers explores applications such as:

- Training future engineers in advanced scanning techniques, highlighting the differences between static and dynamic capture.

- Analyzing body geometry changes during specific activities to optimize garment patterns and improve ergonomic fit.

- Studying the interaction between clothing and the human body in motion to design apparel tailored for specialized technical applications.

- Assessing the best positioning and effect of additional elements —such as protective gear, sensors, or stabilizers— on garment fit and performance.

As Professor Kyosev points out, working with MOVE4D also presents an exciting challenge: “Having the world’s most advanced hardware is just the beginning. From the data MOVE4D generates, we need to develop algorithms and software to evaluate and apply them to our research. And that’s exactly the kind of development process a research institution should embrace.”

You may be interested in: MOVE4D at the 2025 European Defence Innovation Days: A new era of human-centered military design

International recognition and scientific dissemination

The ITM’s advancements using MOVE4D were on full display at the 2021 edition of the “International Conference Clothing-Body Interaction.” This event showcased applied research that highlighted the differential value of high-speed, high-precision 4D scanning technology. Presentations focused on advanced biomechanics, textile modeling, and computational simulation of garments during real human movement.

These contributions, and the interest they generated, reinforced ITM’s leadership in the international research community and confirmed MOVE4D’s role as a key enabler for progress in smart, adaptive textile design.

Technology transfer and global collaboration

TU Dresden and ITM’s experience with MOVE4D has become a benchmark within IBV’s technology transfer strategy. The establishment of the first international lab equipped with MOVE4D marked a milestone for the global rollout of this technology and helped drive adoption by other institutions and companies.

Since its installation in Dresden, MOVE4D has attracted attention from top-tier organizations in sectors such as:

- High-performance sportswear design and manufacturing.

- Defense and technical uniform development.

- Personalized healthcare and orthotics.

- Big Data and digital human modeling.

This growing ecosystem has helped create an international network of centers using MOVE4D as a fundamental tool for improving product ergonomics, body-fit design, and user-centered innovation.

A connected future: Science, design, and technology serving the human body

MOVE4D has proven to be much more than a motion capture system. Its implementation at TU Dresden’s ITM demonstrates its potential to become the core of new workflows in textile engineering, user-centered design, and advanced simulation.

With sub-millimeter accuracy and the ability to capture complex movements at high speed, MOVE4D allows the real behavior of the human body to be fully integrated into the design, development, and validation stages of product creation. This not only enhances fit and functionality but also reduces costs, shortens development cycles, and supports more sustainable industrial processes.

MOVE4D as a global innovation driver

The success story of TU Dresden’s ITM illustrates the transformative potential of MOVE4D in textile R&D and beyond. This pioneering lab was the first international example of how IBV’s 4D scanning technology can become a strategic asset for institutions aiming to lead in digital and personalized product innovation focused on the human body.

At IBV, we continue to expand the reach of MOVE4D through new collaborations, joint research projects, and value-driven solutions that merge science, design, and technology.

Javier Sánchez, Managing Director at IBV, and Beatriz Mañas, Business Development Manager at IBV, state that “We believe the future of product design starts with truly understanding how the human body moves—and we are proud to offer a tool that captures it with unmatched precision.”

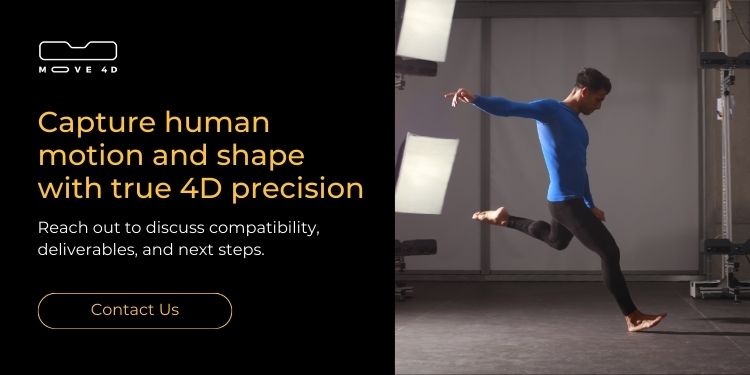

Want to know more about how to integrate MOVE4D into your organization or project?

Contact our team to explore implementation options and tailored collaboration opportunities.